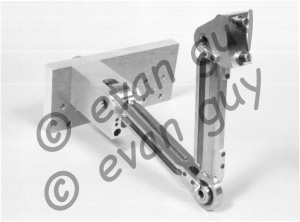

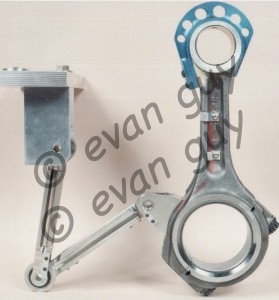

This was a fascinating, but very tedious project. The client provided me with basic kinematic dimensions then gave me “technical blank check” to go do the project. I designed and built this system for gaining important information from the piston of a running Navistar 466 diesel engine. The linkages of this “grasshopper linkage” were machined from solid titanium. The accelerations and velocities were quite high. A lot of detail was given to the flexing of all the wires. The wires would ultimately break as the number of flex cycles increased.

This was a fascinating, but very tedious project. The client provided me with basic kinematic dimensions then gave me “technical blank check” to go do the project. I designed and built this system for gaining important information from the piston of a running Navistar 466 diesel engine. The linkages of this “grasshopper linkage” were machined from solid titanium. The accelerations and velocities were quite high. A lot of detail was given to the flexing of all the wires. The wires would ultimately break as the number of flex cycles increased.

There were 54 leads coming from the piston!! Eddy current probes were carefully embeded in the skirt in four places, 2 places in all 3 ring grooves, thermocouples in many locations, pressure transducers between the piston rings. Whew, very tough job……it was a great success!! Very important data was recorded!

This research yielded information about piston rocking, piston ring reversal dynamics, inter-ring pressures, and operational temperatures in a diesel engine that was running at full speed and full load! That’s not easy or cheap data to get!